What is Circular Knitting?

In the modern textile and clothing industries, mass production is key. Having machines that can produce thousands of pieces of clothing is the best for keeping up with global demand. These are devices with complex engineering behind them and come in a dizzying variety, each with its own purpose and specifications.

If you are in the textile industry, working or operating factories that make clothes, then you have probably looked up a circular knitting machine manufacturer once or twice. These are a critical part of the mass production of various articles of clothing, towels, sportswear, and others. However, just what is circular knitting and what does a machine contribute to that?

The Definition

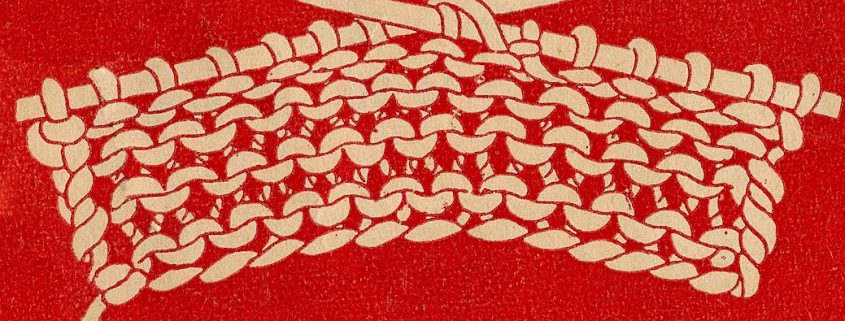

In the textile industry, a circular knit is when the fabric is made into a weft knit. The machine automates this process, either fully or partially. This distinction is focused on how the machines perform the knitting process, rather than the physical properties they result in. As such, a machine that performs circular knitting may be used to make articles of clothing that use a single or double jersey knit.

One machine is capable of producing hundreds, if not thousands, of individual pieces. These can vary from ready to package items to ones that only require some sewing by hand to finalize the details.

The General Process

Now, let’s break down the general process of how circular knitting is done by a machine. First, you need the fabric to be made into clothing and the machine that will do the job. You also require a pattern, which will be the design that’s supposed to come out the other end of the production process. While this can be done on paper, it’s easier to do it digitally and feed it into the machine.

You have the base fabric, typically in the form of a package, that is placed in what’s called a creel. This allows it to be fed into the main “business” parts of the machine, with some designs automating this process while others allow human input to determine when and how much the machine is fed.

The machine can’t just be given yarn right away, of course. The design schematics have to be fed into it, so it knows what to do. This can include details like how much stretching and pressure to apply, along with the overall design of the clothing it’s making. Once these elements are set, then the fabric can be fed into it and it can proceed knitting. Once again, this process can be either automated in full or in part.

In general, a part of the process involves withdrawing the roll fabric for weighing and marking. This will often precede an inspection for quality control, to ensure that the machine is operating properly and the products are being made to specification. If everything passes inspection, they get sent off to the next step of the process.

What Is it Used For?

Circular knitting isn’t used on everything. The type and properties of fabrics that undergo this process are suitable for jackets, sportswear, casual wear, tracksuits, jogging attire, and swimwear. However, depending on the base material, they can also work as gowns, bathrobes, formal dresses, and evening attire.

In some cases, they might also see commercial, non-clothing use. These include household fabrics such as linens and bed sheets. They also see use as upholstery, both for home furnishings and in automotive areas.

Advantages to Using Machines

Apart from the speed of production and consistency of output, there are a few other advantages inherent to the use of a machine for this purpose. The increased precision, for instance, provides for more efficient use of the fabric available. There are less human errors in measurement and quantity of textile used per product.

If the fabric is plated, the result is of higher quality. The needles are smoother as they pass through, causing less chance of physical damage along the way. The typical machine is also designed to have lower friction, while the overall designs help make sure the needles have a longer lifespan. More modern variations of the machine also have lower maintenance requirements, saving on long-term costs.

Specialization Weakness

Circular knitting requires machines specifically designed for the purpose. The other styles of knitting together fabrics into clothing have requirements that aren’t always possible to “translate” onto a machine not built for that function. How difficult this is will vary from model to model, along with specific types of machine. Some industrial knitting models are built specifically for circular knitting and you won’t get the right results if you attempt to have it do something else.

Conclusion

The process of the circular knit is just one of the many ways that the modern world uses to make clothes. With the right fabrics, the machines that perform this can produce some of the best examples of apparel out there. The wide variety of possibilities is very impressive and covers a broad range of products, making circular knitting machines in high-demand in the textile industry.